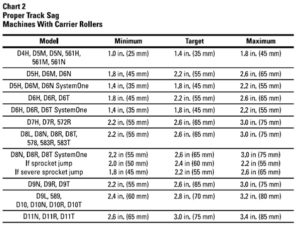

Track Sag measurement differs between elevated sprocket machines with and without carrier rollers and oval track machines. The various measurement guidelines are shown below.

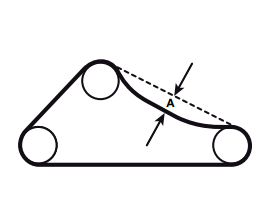

ELEVATED SPROCKET MACHINE

Before measuring Track Sag, move the machine in the forward direction. Allow the machine to coast to a stop without the use of the service brakes or the use of machine and engine stop control. Adjust the tracks while you are in the machine’s typical operating conditions. If packing conditions prevail on the workplace, the tracks should be adjusted without removing the packed material. If the machine is equipped with a ripper attachment, make sure this is completely lift in the raised position, if necessary.

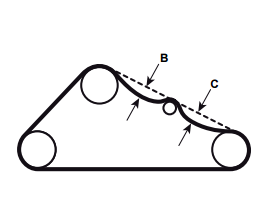

Oval Track Machine

1. Move the machine in the forward direction for a distance of two times the length of the machine. Allow the machine to stop without the use of the service brake, parking brake or machine and engine sop switch. Turn off the engine.

2. Stand on the track between the idler and the track carrier roller and, if your machine is equipped with more than one carrier roller, between the sprocket and the track carrier roller in order to produce as much track sag as possible.

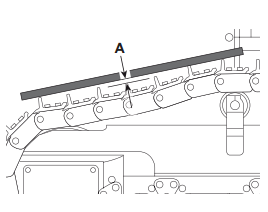

3. Place a straight scale (or string) to the grouser tip on the track shoes that are between the track carrier roller (1) and the front idler (2).

4. Measure the distance (clearance) between the scale and the lowest tip of the grouser that is on the track shoe directly between the idler and the track carrier roller in order to obtain dimension (A).

Note: If your machine is equipped with more than one carrier roller, repeat steps above described to take the clearance between the rear carrier roller and sprocket at the lowest tip of the grouser on the track shoe(B), then use average of readings.

Potential Observations