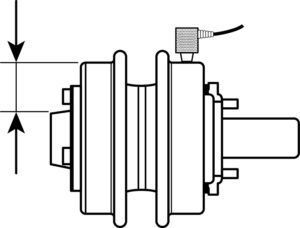

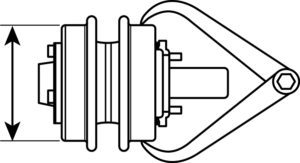

Carrier Rollers can be measured with either an ultrasonic tool or with calipers. Both methods are shown in the videos below.

Potential Observations

What to look for

Below are some of the issues you should be looking for when inspecting carrier rollers. This list does not cover all possible issues, but is a starting point that covers most genral issues.

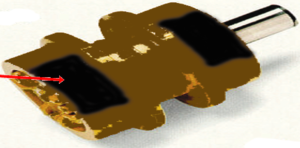

Shaft Breakage

Flat Spots Tread

Off-Center Wear (Tread / Flange)