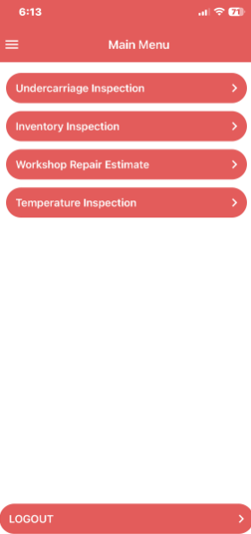

Once you have logged into the mobile app select Undercarriage Inspection

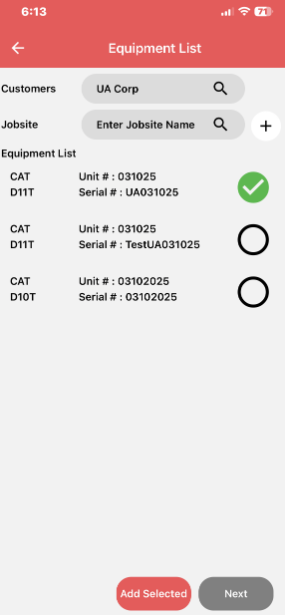

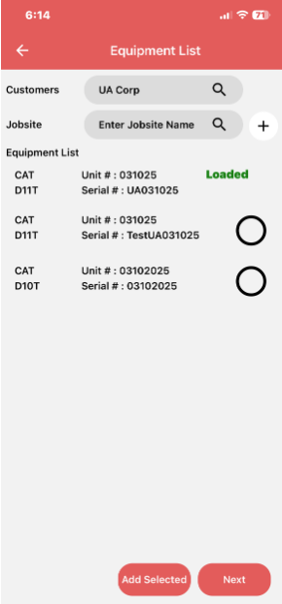

Then click on + Load Equipment

Type in your Customer name or use the magnifying glass to find your customer

Click on the equipment you would like to inspect

Then click Add Selected

Then click on Next

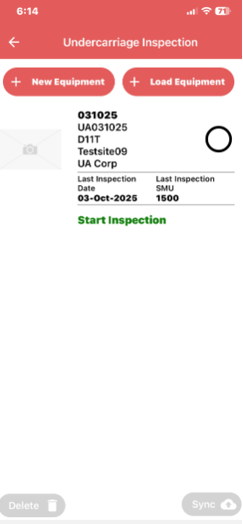

Click on Start Inspection

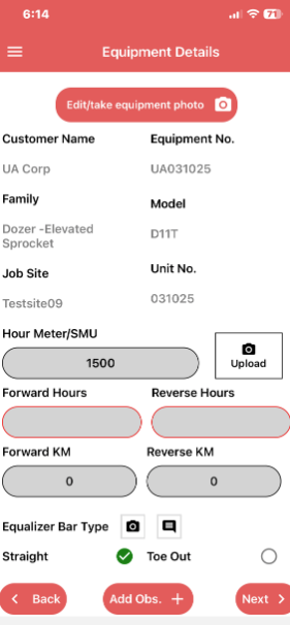

Step 1. START THE INSPECTION

- This displays the Equipment Details, such as:- Family, Model, Unit No, Serial No, Customer Name, Jobsite.

- Take a photo of the equipment in landscape mode

- Input the SMU (Hour Meter Reading) – include an image of the Hour Meter Unit if possible

- Enter the forward and reverse distance in kilometres or miles. (Note can swap between metric and imperial in the Settings Menu – access via 3 bars on the top left of screen to open)

- On large Cat dozers, can also enter information about the equaliser bar and the frame configurations. Images should be included as much as possible.

- Once all complete, click the “Next” button to move to the next page

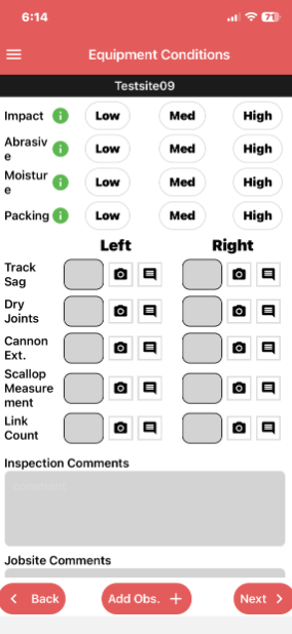

Step 2. EQUIPMENT CONDITIONS

- The following fields are required for User input: Impact, Abrasive, Moisture, Packing

- Can then enter the information for the following fields (Not Required):-

- Track Sag (Left and Right) – chain tension measurement

- Number of Dry Joints (Left and Right) – use infra red camera

- Cannon Extension (Left and Right) – related to track tension and elongation, but ensure not too extended

- Inspector Comments – anything important noted

- Jobsite Comments – specific about jobsite

- Take images and add comments. The images tell a story far quicker than words. Take images in landscape.

- Once complete, click “Next” button

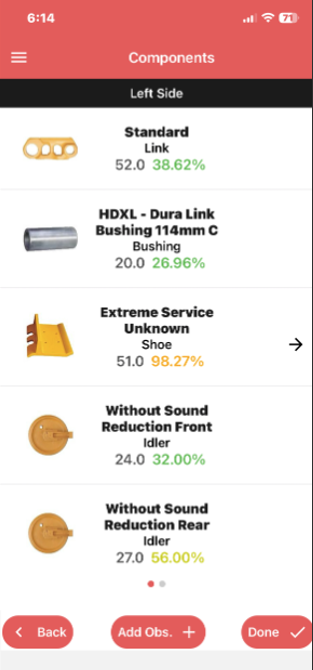

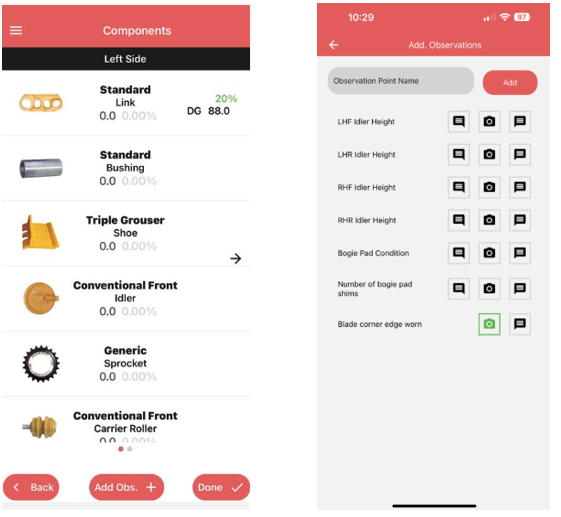

Step 3. Navigate to Summary Components and start Inspecting

- Can select by swiping left and right to select the side to start inspecting.

- Summary displays previous inspection results as well as which components are inspected with images and comments icon. Current inspection results displayed on the right column

Click on a component to inspect that component

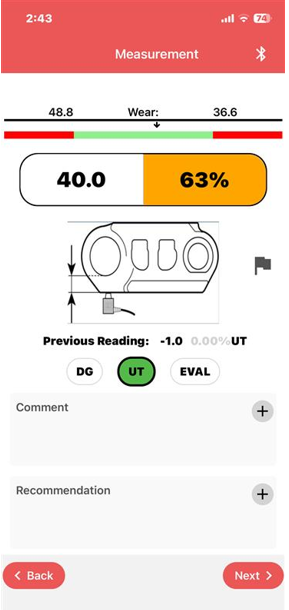

Step 4. Entering the Inspection Data

- This screen displays from top to bottom, first the Blue Tooth button to connect to the Ultrasonic Tool – this turns blue when on. Ensure blue tooth communication set to on in the Cygnus Tool. Also need to select UT as the tool

- Component and camera to take up to 5 images, turns green once image taken

- limits 0 and 100% worn in mm or inches depending on your preference selected

- Reading Input and percent worn calculated once reading has been inputted

- Measurement image for the tools selected

- Flag if this needs to be raised as an alert to a supervisor

- Previous reading with measurement, % worn and Tool used

- Tool selection – only those tools for the specific component will be available and Evaluation which can be used if not sure.

- Comment with Auto Comments indicated with Plus sign – can select and then add further comments by typing

- Recommendations are the Maintenance Actions needed in the future to rectify the current condition where required.

Click the “Next” button to move to the following component. Hit the “Back” button to navigate back to the Summary screen.

To Add Additional Observations

Click on the Add Obs. + button

- Additional Observations allow the recording of any further information for the equipment. Observations can be setup against a family of machines so the same observations appear each time the machine is inspected.

- Observations can be added in the field as you inspect.

- In the Observation Point Name, add in the observation point, and click the Add button

- The observation will appear at the bottom of the screen along with entry of a comment and images.

Once the inspection is complete, hit the Done” button at the bottom of the screen which completes the inspection.