The idler is measured with a depth gauge using four points that are then averaged for the final measurement. The exact process is shown in the video below.

Potential Observations

What to look for

Below are some of the issues you should be looking for when inspecting an idler. This list does not cover all possible issues, but is a starting point that covers most genral issues.

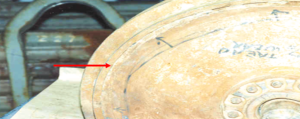

Flattened Tread Wear

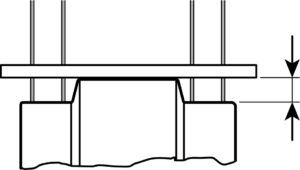

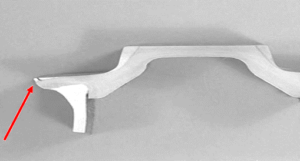

Link Overhang Wear

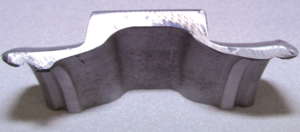

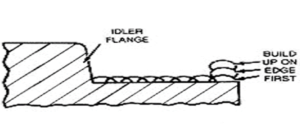

Center Flange Side Wear

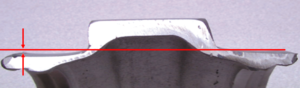

Center Flange Top Wear

Uneven Tread Wear (Inner/Outer)

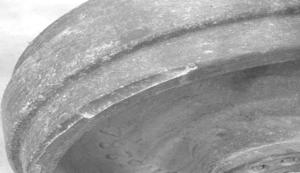

Tread Spalling

Radial Tread Cracking

Idler Side Wall Weld Cracking

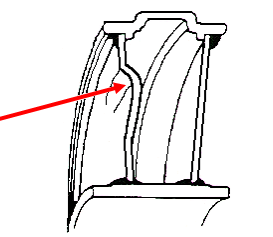

Idler tread Cracking after rebuild

Fabricated Idler Side Plate Damage

Idler Tread Wear Difference Front to Rear

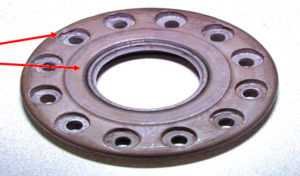

Idler retainer Wear