The system records three hour readings.

- SMU is the current meter reading of the machine. This would indicate the entire life of the machine ONLY if it is the original meter. If the meter is changed this will only show the reading of the new meter. This figure is a round number and does not allow decimals. The SMU is originally set at equipment setup and then updated when an inspection is added, the meter is updated or replaced and when an action is entered against the machine.

- LTD is the Life To Date. This shows the entire life of the machine. This will be the same as the SMU is the HAS NOT been replaced. If the meter has been replaced this will show the total hours of the machine regardless of what the current meter (SMU) shows. The LTD is a calculated field and cannot be set directly by the user except at original equipment setup.

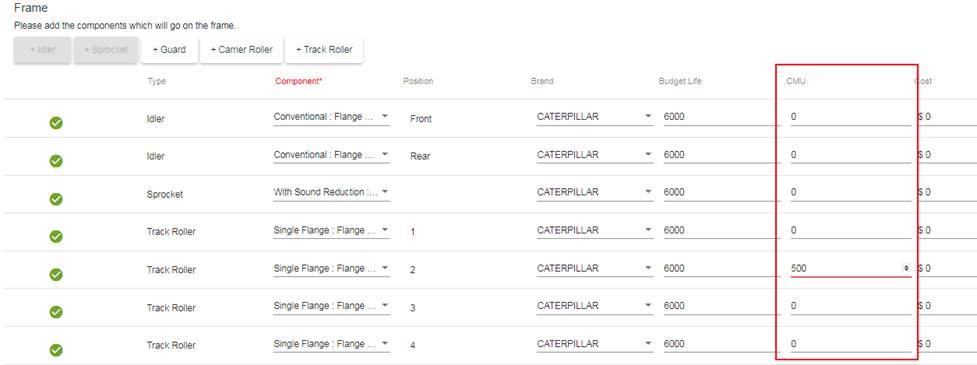

- CMU is the component hours. This figure shows how many hours the actual component has done. When the component is installed the SMU is recorded at the time and the hours are then calculated from that SMU to the current SMU. If used components are fitted to a machine the number of hours they have already done can be recorded and those hours will contribute to the total CMU of the component.

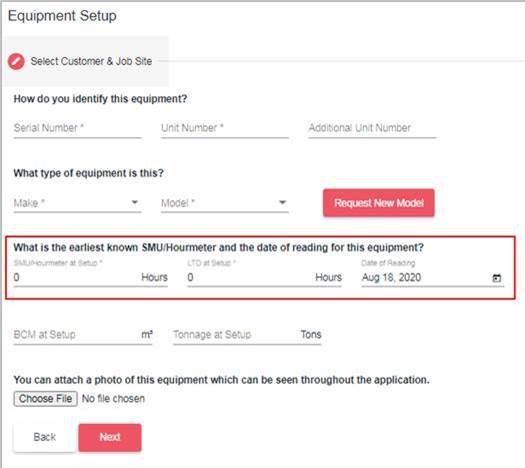

Setting the Original SMU and LTD

When a machine is first setup through the create new machine process, the SMU and LTD at time of setup is entered. As components can be installed with an earlier date and SMU, and no inspections or actions can be entered before this date, it is advised to use the earliest known Date and SMU for the machine. If you do not plan on entering the full and complete history of the machine, we recommend using the Date and SMU of when the current undercarriage was installed.

As a general rule, the equipment setup will not be changed after it is first set unless a mistake has been identified. Changes to equipment setup are allowed after the first inspection has been entered to allow for mistakes being discovered when the machine is first inspected. Once a second inspection has been entered the equipment setup is locked.

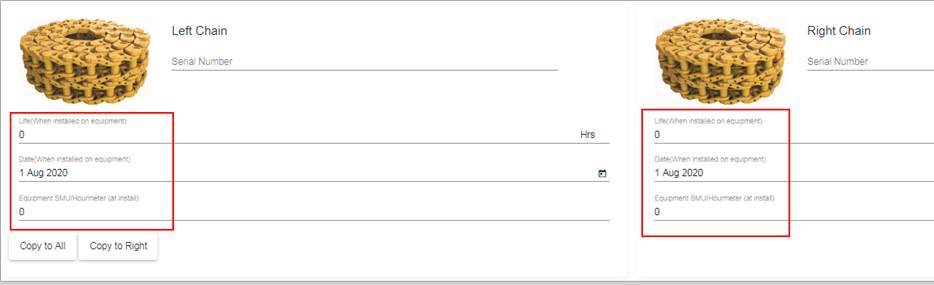

Undercarriage Setup

As part of the original equipment setup, you will setup the undercarriage on the machine. As mentioned above, unless you plan on entering the full history of the machine, including all undercarriage replacements and other actions, we recommend using the date, SMU hours and component details of the currently fitted undercarriage. During the undercarriage setup you can enter date and SMU at the time the Chains and Frames were fitted to the machine.

You can also record the hours the undercarriage components had on them at the time they were fitted if they were second hand and differ to the actual system hours. For example, the frame may have had a new or used roller added that has different hours to the rest of the components. Also, if you have setup the equipment with a date and SMU that is after the time they were fitted, you can enter the number of hours the components had on them at that point in time. As with the Equipment setup, Undercarriage Setup can only be changed before the second inspection has been entered. This allows for corrections to mistakes that have been picked up during the first inspection. After the second inspection all changes are made through the Actions process.

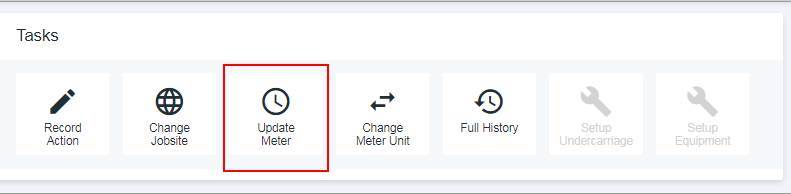

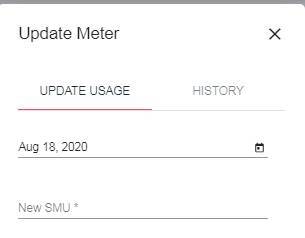

Update Meter

To allow the most recent SMU hours to be entered, you can use the Update Meter button on the equipment details screen. This is a simple popup where you can record a Date and SMU reading. The Date and SMU combination you enter must be valid for the existing data that has been entered in the system and be AFTER the most recent Date and SMU reading from Setup, Inspections, Meter Update or Actions.

Recording an Inspection

As part of recording an inspection, the SMU of the machine is recorded. When the inspection is added to the system the SMU is recorded and used to calculate the life of the components at the time of inspection and to update the equipment SMU and LTD. As mentioned above, once 2 inspections have been recorded against a machine, the Equipment Setup and Undercarriage Setup screens are locked and no further changes can be made to the original setup.

Adding Actions

After the original setup, Actions are used for recording all changes to the undercarriage. This includes repairs, Turning of bushings and replacements of single components or entire groups of components (i.e. new chains or frames).

Recording actions is something I will go through independently as there are many options and scenarios to cover, but for the subject at hand, it is enough to say that all actions are recorded with the date and the SMU of the machine at the time the action was recorded. If this is the most recent SMU it will update the machine SMU and LTD, and recalculate the CMU of the components. If it is not the most recent date and SMU, the CMU of affected components will be updated. Actions can be recorded after or before the most recent inspection. This allows for cases where a component replacement is not discovered until the inspection is done and the replacement needs to be recorded in the system to have occurred before the latest inspection.